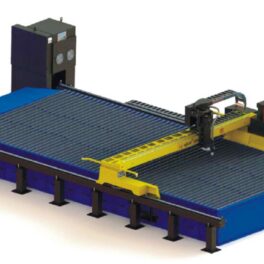

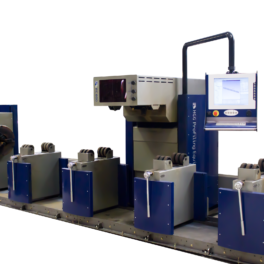

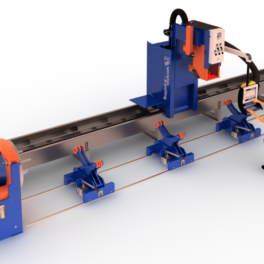

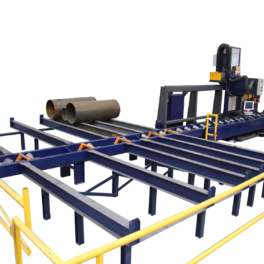

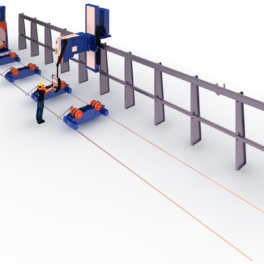

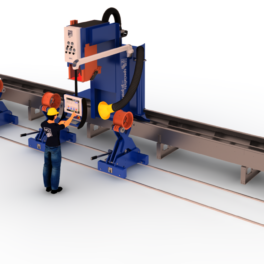

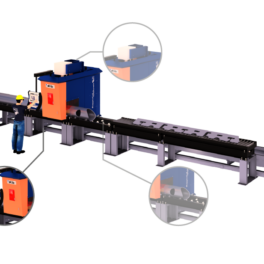

Nordcity Center plasma cutting machines

40 years of experience in the electronics industry has made AJAN probably the most reliable manufacturer of gas and plasma cutting machines in the world, capable of independently producing all its machine components. Products are available for both small and large manufacturers. The prices of equipment and consumables are low, as AJAN manufactures the equipment entirely in-house. In addition, the manufacturer has pointed out that all the benches that have been in operation since the beginning (even 40 years old) and have been properly maintained are still in operation today.

Durmazlar is characterized by a wide range of high-quality metalworking equipment – from manually operated guillotines to high-tech CNC laser cutting and bending machines. In addition, the company offers high-quality service, customer support, and training. The company also offers off-the-shelf spare parts, which means that it takes significantly less time to repair faulty equipment.

About Plasma Cutting

Plasma cutting is a melting process in which a stream of ionized gas at over 30,000 ° C is used to melt and remove material from the cut. The electrode is a water- or air-cooled gas nozzle that produces a focused, high-temperature, high-speed plasma flow.

Advantages of plasma cutting

- Ability to cut many types of metals: plasma cutters can cut non-ferrous metals such as aluminum, stainless steel, and cast iron – materials that are increasingly common in many end products and solutions.

- Cutting accuracy: plasma cutters typically cut quickly and with minimal mess, providing smoother cuts compared to oxy-fuel torches.

- No preheating required: plasma does not require preheating to cut metal. Consequently, you save time and money.

- Higher speed on thinner metals: plasma can cut thinner metals faster than oxy-fuel equipment while ensuring minimal metal distortion. Plasma also offers better performance when cutting stacked metals.

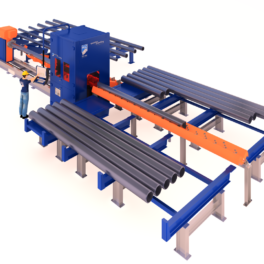

Better cutting of shaped metals: where the workpiece has corners, channels or tubes, plasma cutting can provide faster and more accurate cutting results. - Ease of use: plasma systems are relatively easy to use compared to oxygen-based fuel systems.

- Safer: plasma systems do not require the storage and handling of explosive gases or the use of open flames.

Nordcity Center sells plasma cutting machines (gas cutting is usually available as an option) for sheet metal as well as tube and profile processing. A wide range of numerically controlled CNC plasma cutting machines is available. We would like to find the best possible machine for your company to meet your needs. Feel free to contact us!